- Commercial 3D printers & additive manufacturing solutions

- Order sample print

- 3D Printers

-

Industries

-

3D Printers for Architects

3D printers for BIM, Architecture & AEC

- Objet30 Pro 3D Printer

-

Automotive

- ABS-like

- Fortus 380 Carbon Fiber

- High Temperature

- Nylon 12

- Objet Eden500V

- Objet1000 3D Printer

- Objet30 Pro 3D Printer

- Objet350 Connex

- Stratasys Dimension 1200es Series

- Stratasys Fortus 250mc

- Stratasys Fortus 360mc

- Stratasys Fortus 900mc

- Stratasys Mojo 3D Printer

-

Consumer Electronics

- ABS-ESD7 - static dissipative properties

- ABS-like

- High Temperature

- Nylon 12

- Objet Eden500V

- Objet30 Pro 3D Printer

- Objet350 Connex

- Rigid Opaque

- Rubber-like

- Stratasys Fortus 250mc

-

Consumer Goods

- Nylon 12

- Objet Eden500V

- Objet30 Pro 3D Printer

- Objet350 Connex

- Polypropylene-like

- Rigid Opaque

- Rubber-like

- Stratasys Fortus 250mc

- Stratasys Fortus 900mc

- Stratasys J55

- Stratasys Mojo 3D Printer

-

Aerospace & Defence

- ABS-ESD7 - static dissipative properties

- Objet Eden500V

- Objet1000 3D Printer

- Objet30 Pro 3D Printer

- Objet350 Connex

- Stratasys Dimension 1200es Series

- Stratasys Dimension Elite 3D Printer

- Stratasys Fortus 250mc

- Stratasys Fortus 360mc

- Stratasys Fortus 900mc

-

Dental

- Bio-Compatible

- Dental Materials

- Objet Eden260V Dental Advantage

- Objet350 Connex

- Transparent

-

Education

- Educators

- Researchers

- Students

- MakerBot Method

- Objet Eden500V

- Objet1000 3D Printer

- Objet350 Connex

- Stratasys Dimension 1200es Series

- Stratasys Dimension Elite 3D Printer

- Stratasys Fortus 250mc

- Stratasys Fortus 360mc

- Stratasys Fortus 900mc

- Stratasys Mojo 3D Printer

-

Entertainment

- Objet1000 3D Printer

- Stratasys Fortus 250mc

- Stratasys Fortus 900mc

- Stratasys Mojo 3D Printer

-

Hearing Aids

- Dental Materials

- Hearing Aids

- Objet350 Connex

- Transparent

-

Industrial Machinery

- Desktop Metal Studio System 3D Printer

- High Temperature

- Nylon 12

- Objet Eden500V

- Objet1000 3D Printer

- Objet30 Pro 3D Printer

- Objet350 Connex

- Stratasys Dimension 1200es Series

- Stratasys Fortus 250mc

- Stratasys Fortus 360mc

- Stratasys Fortus 900mc

-

Jewellery

-

Medical

- Dental Materials

- Nylon 12

- Objet Eden500V

- Objet350 Connex

- Transparent

-

Medical Equipment

- Nylon 12

- Objet1000 3D Printer

- Objet350 Connex

- Polypropylene-like

- Stratasys Dimension 1200es Series

- Stratasys Fortus 250mc

- Stratasys Fortus 360mc

- Stratasys Fortus 900mc

-

Packaging

- Polypropylene-like

- Transparent

-

Service Bureaus

- Nylon 12

- Objet Eden500V

- Objet1000 3D Printer

- Objet30 Pro 3D Printer

- Stratasys Fortus 360mc

-

Sporting Goods

- Polypropylene-like

- Stratasys Mojo 3D Printer

-

Toys

- Rigid Opaque

- Rubber-like

- Stratasys Fortus 250mc

-

-

Brand

-

Desktop Metal

- Desktop Metal Studio System 3D Printer

-

Stratasys

Our Stratasys range

- 3D Printing for Direct Digital Manufacturing

- ABS-ESD7 - static dissipative properties

- ASA Thermoplastic

- Dental Materials

- Digital Materials | 3D Materials

- Fortus 380 Carbon Fiber

- Hearing Aids

- Nylon 12

- Objet Eden250

- Objet Eden260V

- Objet Eden260V Dental Advantage

- Objet Eden260VS

- Objet Eden350V

- Objet Eden500V

- Objet Water Jet Support Material removal System

- Objet1000 3D Printer

- Objet260 Connex

- Objet260 CONNEX1 3D Printer

- Objet260 CONNEX2 3D Printer

- Objet30 Prime 3D Printer

- Objet30 Pro 3D Printer

- Objet350 Connex

- Objet500 Connex 3D Printer

- Objet500 Connex1

- Objet500 Connex2

- Objet500 Connex3 3D Printer

- Stratasys Dimension 1200es Series

- Stratasys Dimension Elite 3D Printer

- Stratasys Dimension SCA-1200 Support Removal System

- Stratasys F170 3D Printer

- Stratasys F270 3D Printer

- Stratasys F370 3D Printer 3D Printer

- Stratasys Fortus 250mc

- Stratasys Fortus 360mc

- Stratasys Fortus 380mc Production 3D Printer

- Stratasys Fortus 400mc 3D Printer

- Stratasys Fortus 450mc Production 3D Printer

- Stratasys Fortus 900mc

- Stratasys J55

- Stratasys J850

- Stratasys Mojo 3D Printer

- Stratasys uPrint SE 3D Printer

- Stratasys uPrint SE Plus 3D Printer

- Stratasys Wavewash 55

- ULTEM 1010

-

Makerbot

Our Makerbot range

- MakerBot Method

- Makerbot Replicator Mini

- Makerbot Replicator Z18 3D Printer

-

Autodesk

Our Autodesk products

- AutoCAD Inventor LT Suite

- Autodesk 3D Max

- Autodesk Inventor

-

- Materials

- Accessories

- Software

- Applications

-

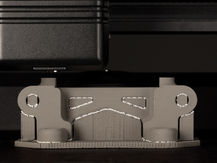

Desktop Metal Studio System 3D Printer

The Desktop Metal DM Studio System is the world’s first affordable, office-friendly metal 3D printing system. Safe and simple to use, the DM Studio System was designed to bring metal 3D printing to the shop floor by allowing engineering and design teams to make metal parts faster, without the need for special facilities or dedicated operators.The Desktop Metal Studio System 3D Printer is great for:

- Fast material changes

- Cost effective metal printing

- Office-friendly metal 3D printing

It’s built on a cloud-based software architecture, the DM Studio System enables the user to go directly from CAD to part. By having one software platform across the system, designers and engineers can work with one digital file for a metal part throughout its entire lifecycle instead of needing to use 3rd party equipment and software to get a final part.

Very similar to FDM (fused deposition Modelling) the Studio printer prints out a “green” part layer-by-layer by heating and extruding specially formulated bound metal rods. After this process and once the part has been printed out on the bed, it is sintered. A portion of the plastic binder is first removed, and then the furnace heats the part to temperatures close to melting point, thus causing the metal powder to densify.

With hand-removal of supports, fast material changes, and web-based software being just a few ways Desktop Metal are making metal 3D printing more accessible. The Studio system was designed from the ground up for simple installation and use.

A unique ground breaking furnace system dovetails with a cloud based operating system whch provides an end to end 3D metal printing solution

Enquire about this

printer

- Materials

- Tech Specs

- 200+ compatible alloys

- Designed to use MIM (Metal Injection Molding) materials

- Including but not limited to - steels and aluminum to superalloys and titanium

- Laser-based systems require specially formulated, cost-prohibitive metal powders with Desktop metal you can use metal powder with a wide particle size distribution, enabling much lower materials costs - up to 80% Cheaper

- Max Resolution: 50um

- Speed: 1inches3/hr

- Build area: h300mm, d200mm, w200mm

- Nozzle diameter: 0.4mm

- Print Technology: Bound Metal Deposition (BMD)

- Support Structures: Separable supports

Worcester (Head Office) 01905 458 000

Worcester (Head Office) 01905 458 000 3d@stanfordmarsh.co.uk

3d@stanfordmarsh.co.uk